MIM-technology

MIM stands for Metal Injection Molding. This technology is a viable and rapidly developing metalworking process that brings together traditional plastic injection molding and metal powder sintering. Metal components manufactured via the MIM technology offer complex shape design, as well as strong mechanical properties. The end-product made by MIM has comparable mechanical and physical properties with parts made using classic metalworking methods. MIM materials are compatible with the same subsequent metal conditioning treatments such as plating, passivating, annealing, carburizing, nitriding, and precipitation hardening.

The technology involves the following process stages:

– “feedstock” mix preparation from metal powders and – plastic binding elements

– injection of liquified feedstock into a hollow mold using a plastic injection molding machine

– debinding via a solvent/thermal process

– sintering

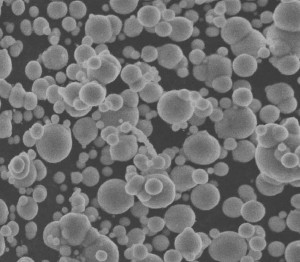

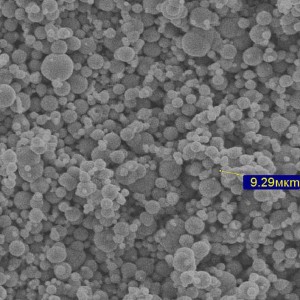

HC-C1 (featuring anti-agglomeration coating)

As metal injection molding is still a branch of powder metallurgy technology, the choice of metal powders for creating optimal feedstock is very critical. Currently there is a number of materials available on the market that offer advantages as well as disadvantages that may not be obvious immediately.

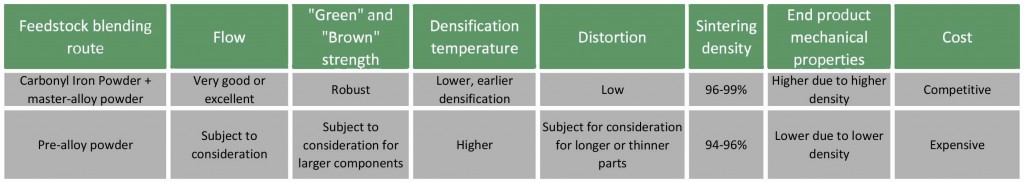

For most of the iron-based materials (4605, Fe2Ni, Fe8Ni, 316L, 17-4PH, 4140, 4340, etc.) there are 2 most widely used routes for creating MIM feedstock:

– mix Carbonyl Iron Powder and master-alloy (concentration) powder of the corresponding alloy

– use pre-alloy material powder, prepared by atomizing the ready-alloy heat

The CIP+MA route offers a number of advantages, especially for low alloy steels: such as carbon control, earlier densification, low distortion, higher density and better mechanical properties but lower costs.

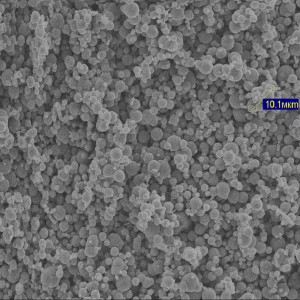

НС-2

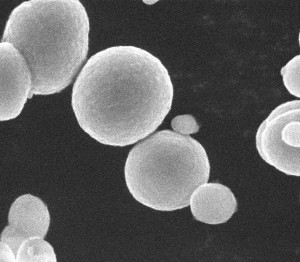

Carbonyl iron powder by Sintez-CIP features:

– excellent flow

– increased tap densities

– uniform packing

– carbon control

– batch-to-batch consistency

– competitive pricing

Sintez-CIP offers a choice of grades, specifically designed for metal injection molding application: ВС, ВС-С, НС, НС-2, НС-С1, НМ, or HM-C. Please send us your inquiries via our contact page. SPC data is available upon request.